Learning The Charcoal Manufacturing Process

Charcoal is nothing more than the residue from the whole process of experiencing pyrolysis. For example, whenever you take materials that are made from petrochemicals, such as rubber or plastic, these may be reconstituted back into their original forms. This is accomplished by way of a process of heat, absent the combustion process, therefore allowing the physical component being burned at another time. A good example of this is placing plastic in to a pyrolysis reactor. The physical byproduct will likely be charcoal. There is certainly more for this process which will now discuss.

Charcoal Manufacturing Process

Charcoal Manufacturing Process

How Is Charcoal Made?

At the very basic level, a tree might be chopped down, or organic material can be placed right into a mold or perhaps covered to ensure oxygen cannot burn it thoroughly through. Once this is accomplished, the physical dark matter is solid, and will also become the charcoal. This is what many countries use that get access to forests where they may slash and burn them for this purpose. However, from a recycling perspective, using material including rubber and plastic can be used inside a similar manner. These are typically chipped up into smaller pieces and placed into a pyrolysis machine. Within the reactor, the same process will occur, with a lot more byproducts including bio oil and bio fuel.

Do You Want A Pyrolysis Machine To Get This Done?

It can do increase the procedure of deteriorating materials that can eventually become some form of charcoal. If you use organic material, for example, you will not have a unit and it could take about eight hours to perform the charcoal manufacturing process. However, if you are dealing with materials like rubber and plastic, these have to be placed within a device that features a pyrolysis reactor where this chemical process could be induced. Within hours, you might have a large amount of charcoal willing to use, or willing to ship to customers which will purchase it.

What Is The Best Process For Producing The Charcoal?

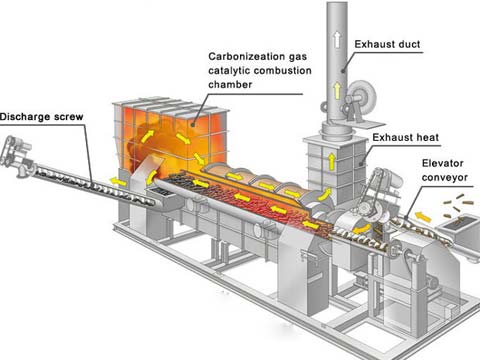

The most effective process is by using an entire system that will add a machine that can perform pyrolysis. You should have a device which will breakdown the primary materials into smaller components. These will probably be placed in the reactor, and after a time period of time, the liquid biofuel and bio oil will likely be produced. Once those are extracted, the other material is going to be charcoal which you can use for burning. These will be put in to a storage facility for later use or perhaps to get ready for shipping. Ask for price here: https://kingtigergroup.com/charcoal-making-machine-price/.

Minus the advance from the pyrolysis reactor, the creation of charcoal will be quite slow. You might additionally be limited to using organic materials. Fortunately, technologies have made it feasible to transform rubber and plastic into charcoal in a really minimal length of time. Although these could be expensive, they will a lot more than buy themselves along with your initial investment within the duration of just a couple of years. You can select from substantial pyrolysis plants, all the way down to smaller pyrolysis machines designed for individual use. These can make a massive difference in terms of protecting the surroundings from problems due to landfills.